Dank der zahlreichen Vorteile des Shape-from-Colour-Verfahrens hat visicontrol nun eine leistungsstarke, zusätzliche Technologie eingebunden, die topografische Defekte auch unter anspruchsvollen Bedingungen prozesssicher erkennt….

The reliable detection of attributive defects belongs to the premier class of industrial image processing. While dimensional inspections are a mathematical problem and can usually be solved with the help of high-resolution cameras and optics, the problem of attributive defects is more difficult.

visicontrol hat sich früh auf diese Art der Fehlererkennung spezialisiert und im Lauf der Jahre unzählige Module sowie Technologien für die Prüfautomatisierung entwickelt.

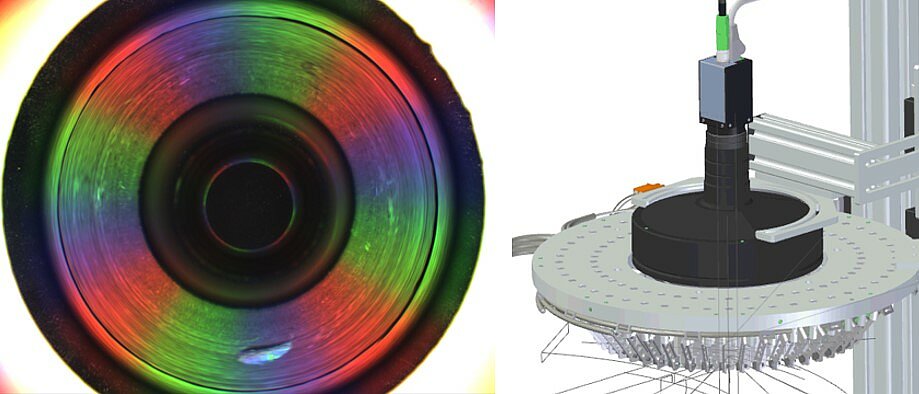

visicontrol also develops and patents its own technologies. The Shape from Colour (SFC) process was developed by visicontrol and is patent pending.

Thanks to the advantages of the SFC process, visicontrol has now integrated an additional technology that reliably recognises topographical defects. The module is already integrated in our innovative image processing software visiTeach+ integriert. Die Auswertung kann, wie auch andere Verfahren aus dem Hause visicontrol, mithilfe von KI erfolgen. Dadurch lassen sich auch komplexe Oberflächenstrukturen zuverlässig analysieren, ohne auf teure oder mechanisch aufwändige Prüfmethoden zurückgreifen zu müssen.

The advantages are obvious:

- World's first 360° inspection method for topological defects

- Dynamische Prüfung von 360°-Mantelflächen oder Planflächen z.B. auf der visiSort-T

- Can be used in all visicontrol test automation systems

- Already integrated in visiTeach+

- Tested and reliable functionality

The more than 200 modules of our visiTeach+ image processing software can reliably detect numerous defect features. Coupled with our expertise in the field of bulk material inspection and sorting as well as in-line inspection solutions, visicontrol has a broad portfolio to offer. In the more than 30 years since its foundation, 3900 different inspection solutions have already been successfully implemented at leading companies worldwide.

Durch die Kombination von Hard- und Softwarelösungen sowie kontinuierlicher Weiterentwicklung zählt visicontrol zu den Technologieführern im Bereich der industriellen Bildverarbeitung. Mit dem SFC-Modul wird dieses Know-how gezielt erweitert – für noch präzisere und effizientere Prüfprozesse.