visicontrol is known for innovative state-of-the-art image processing solutions for various industries worldwide. The systems usually run 24/7 on more than 350 days a year. With high self-sufficiency and unparalleled reliability, we keep the support effort by skilled personnel as low as possible - a contribution against the shortage of skilled personnel.

Components made of sintered materials and ceramics are among the most sought-after and highest-quality components today. The advantages in manufacturing make it possible to continue to produce locally in high quantities; "Made in Germany" despite increased personnel and energy costs. A 100% inspection of these components is necessary and critical for the manufacturers. In one of the recently delivered systems, we were able to achieve inspection rates of over 450 parts/min despite surface inspections, which means over 70 million parts per year in the final expansion stage. The investment costs are thus amortized within a few months.

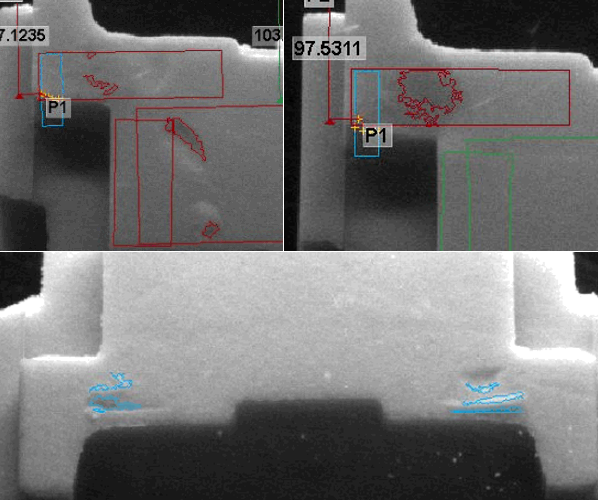

Typical defect characteristics of sintered parts and ceramics include:

- Caking

- Breakouts

- Cracks

- Foreign bodies

- Discolourations

- Surface defects

- Dimensional inaccuracy

Many of the defects mentioned belong to the class of attributive defect features and are considered to be the most difficult of their kind. With the latest technology and innovative illumination scenarios, visicontrol was able to realize a process-safe inspection scenario. Multiple cameras instead of mirror optics and customized inspection programs now enable the customer to take a big step towards a 0ppm defect rate.

With over 200 modules, our visiTeach+ image processing software can detect countless defect features with high process reliability. Coupled with expertise in bulk material inspection and sorting as well as in-line inspection solutions, visicontrol has a broad portfolio to offer. In more than 30 years since its foundation, over 3800 different inspection solutions have been successfully implemented at leading companies worldwide.

visicontrol is your partner for innovative and flexible inspection automation.